Large cold storage with refrigerator unit

- Product Name:Large cold storage with refrigerator unit

- Model:50,75,100,120,150,175,200,250mm

- Size:960mm~1200mm

- Package:Standard Seaworthy Package

1、Name: Large cold storage with refrigerator unit

2、Product description:

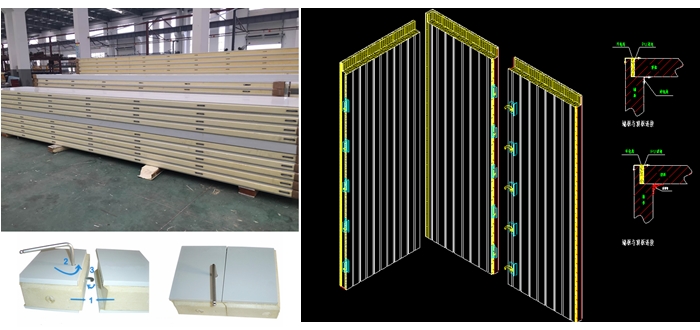

- Cool storage sandwich panels usually are using metal sheet as finishing surface, and polyurethane (PU),or polyisocyanate (PUR), or polyisocyanurate (PIR) as core material.

- They are locked together by cam locks on each side of the panels to ensure airtight joints.

- Cam-lock design can help to install with the cold rooms tightly and strongly.

- Silica gel are used on the cold room door panel edge of the joint parts of each sandwich panel to ensure perfect sealing to avoid the cooling air leakage from the cool room or moisture inside the insulated panel for the best refrigeration and frozen storage result.

3、Product features & Advantages:

- Customized design

- Fire retardant

- Meets safety requirements

- Energy saving

- Longer lifetime

- Resistant to termites and rodents

- Easy to install – saving cost of installation time • High performance on insulated panel

4、Specification & Technical standard

|

Specification |

||

|

Width |

Standard width960mm, or customized and maximum 1200mm |

|

|

Length |

as customers' requirements, maximum 12000mm |

|

|

Thickness |

50mm |

≥ 15ºC |

|

75mm |

≥ 10ºC |

|

|

100mm |

≥ -15ºC |

|

|

150 mm |

≥ -25ºC |

|

|

200 mm |

≥ -35ºC |

|

|

250 mm |

≥ -45ºC |

|

|

The most suitable thickness will be suggested according to the size and temperature requirements, or customers' requirements |

||

|

Surface Metal |

0.3~1mm Color steel sheet(pre-painted iron sheet) 0.4~1mm stainless steel sheet 0.5~3mm aluminum sheet 0.5~2mm galvanized steel sheet |

|

|

Core material |

PU(polyurethane ) /PUR(polyisocyanate )/PIR(polyisocyanurate) |

|

|

Joint system |

Cam lock, tongue & groove, hook & pin |

|

|

Technical Standard |

|||

|

PU/PUR/PIR |

PU |

PUR |

PIR |

|

Density |

40±2 kg/m3 |

40±2 kg/m3 |

45±2 kg/m3 |

|

Heat Conductivity |

≤0.024 W/m. k |

≤0.024 W/m. k |

≤0.022 W/m. k |

|

Compressive Strength |

≥150 N/cm2 |

≥150 N/cm2 |

≥160 N/cm2 |

|

Combustion performance |

B2 grade |

B2 grade |

B1 grade |

|

The bond strength between sandwich core layer and panel |

>0.1 |

>0.1 |

>0.1 |

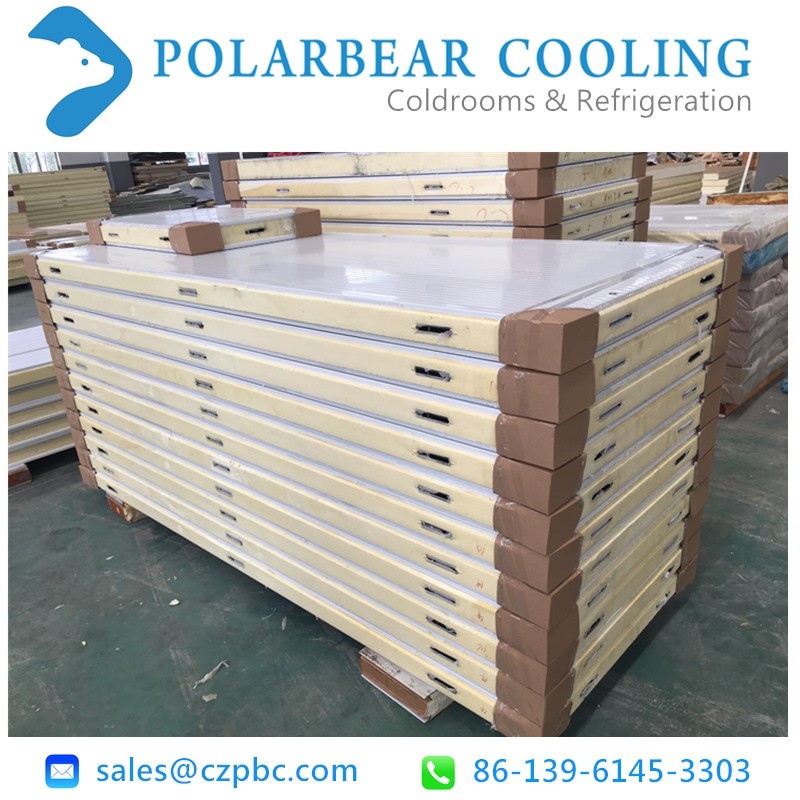

5、Packing & shipping

- Packaging Details:

--Free packing (with normal pallet and packing belt)

--Standard exporting packing (wrapped with plastic thin film, wedge protect and good pallet or as customer’ requirements).

- Peak season lead time: 15days & Off season lead time: 7days.

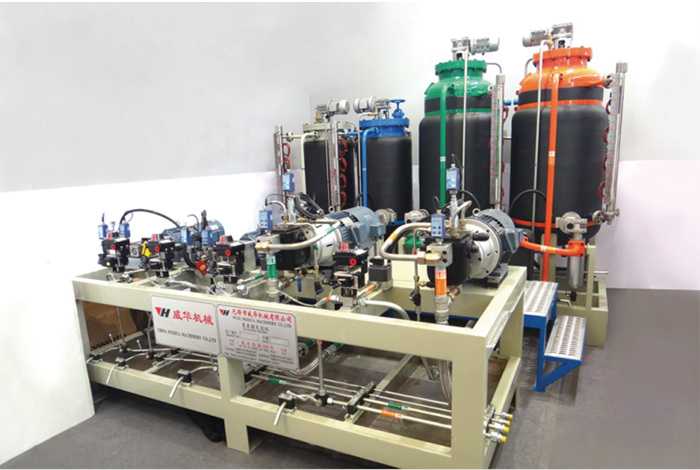

6、Production flow

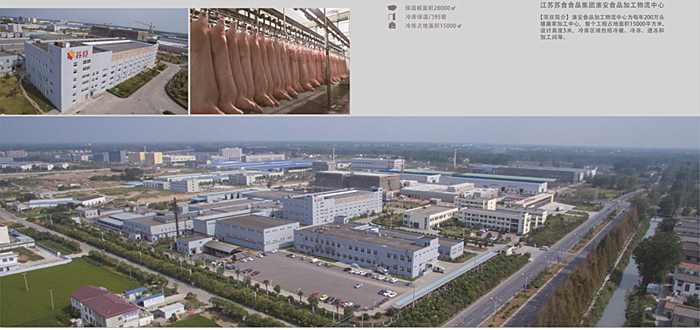

7、Main application

Food(meat, vegetables,fruit,dairy,drink),medicine,chemical,electronics,etc.

-

Cold Storage Room For Cheese

The storage temperature kept at 0℃,the cold panel thickness is 75mm.

-

Cold Storage Room For Vegetable

The storage temperature kept at 0℃,the cold panel thickness is 75mm.

-

Cold Storage Room For Fruit

The storage temperature kept at 0℃,the cold panel thickness is 75mm.

-

Cold Storage Room For Medicine

The storage temperature kept at -5℃,the cold panel thickness is 75mm.

-

Cold Storage Room For Beverage

The storage temperature kept at -5℃,the cold panel thickness is 75mm.

-

Cold Storage Room For Fish

The storage temperature kept at -28℃,the cold panel thickness is 100mm.

-

Cold Storage Room For Meat

The storage temperature kept at -28℃,the cold panel thickness is 100mm.

- Cold Storage Room For Cheese

- Cold Storage Room For Vegetable

- Cold Storage Room For Fruit

- Cold Storage Room For Medicine

- Cold Storage Room For Beverage

- Cold Storage Room For Fish

8、Case display

9、About us

Changzhou Polar Bear Cooling Co., Ltd was founded in 1996. Our company is a first-class cold storage insulation materials manufacturer and a cold storage energy-saving program supplier. We focus on the field of cold storage materials and cold storage research and development areas, through years of great-leap-forward development, the company is expanding, now has 28 management staff, 15 technical staff and 170 engineering installation and production staff. The company has established two production bases, covers an area of more than 80 acres, adopt the most advanced in domestic and international third-generation automatic continuous production line, which improves the capacity of production and supply for various types of products. At present, the annual output of our company is thermal insulation materials up to 1.5 million square meters, all kinds of cold storage doors 8, 000 sets, industrial unloading platform 1, 500 sets, all-round to meet the various needs of customers.

High quality cold store sandwich panel

View Detail

Walk in coolroom for fruits

View Detail

cold store PU sandwich panels price

View Detail

PIR sandwich panel for roof

View Detail

Walk in cold room manual sliding door for coolroom

View Detail

Evaporative air cooler for cold room

View Detail

Best and cheaper evaporative air cooler

View Detail

Evaporative Fan For Refrigeration Equipment

View Detail

Electric/Manual sliding door for cold coolroom

View Detail